- +86 138 5797 0150

- admin@bottle-iar.com

- Mon - Fri: 00:00 - 23:59

Glass Bottle

China has had glass bottles since ancient times. Past academic beliefs held that glassware was quite rare in ancient times and thus should have been possessed and used only by a small ruling class. However, recent research suggests that the production and manufacturing of ancient glassware were not particularly difficult, but its susceptibility to degradation led to its scarcity in later discoveries. Glass bottles are a traditional beverage packaging container in China, and glass is a packaging material with a long history. Despite the influx of various packaging materials into the market, glass containers still hold a significant position in beverage packaging, thanks to their unique packaging characteristics that are irreplaceable by other materials.

I. Basic Information

Chinese Name: 玻璃瓶 (Bōlí píng)

English Name: Glass bottle

Recycling: Recycling saves energy

Earliest Appearance Time: Han Dynasty

II. Table of Contents (Translated & Expanded for Clarity)

Recycling

Gourd-Shaped Glass Bottle (Tang Dynasty)

Spraying Process

Blow-off and Purification Section

Packaging Industry

Museum

Manufacturing Process

Quality Standards

Energy Saving and Environmental Protection

Process Flow (Detailed)

Quality Standards & Standardization System (Detailed)

Energy Saving & Environmental Protection (Detailed)

III. Recycling

Glass bottle recycling amounts increase every year, and this recycled quantity is massive and immeasurable. According to the Glass Packaging Institute: the energy saved from recycling one glass bottle can power a 100-watt light bulb for about 4 hours, run a computer for 30 minutes, or power a television for 20 minutes. Therefore, recycling glass is highly significant. Recycling glass bottles saves energy, reduces the volume of waste in landfills, and provides more raw materials for other products, including new glass bottles. According to the National Post-Consumer Plastics Bottle Recycling Report by the American Chemistry Council, approximately 2.5 billion pounds of plastic bottles were recycled in 2009, a recycling rate of only 28%.

IV. Gourd-Shaped Glass Bottle

Glass containers began to appear in the Han Dynasty, such as the glass plate with a diameter of over 19 cm and the glass ear cup measuring 13.5 cm long and 10.6 cm wide unearthed from the tomb of Liu Sheng in Mancheng, Hebei. With developed transportation routes to the West during the Han Dynasty, foreign glassware would have been imported into China. For example, three fragments of purple and white glass were unearthed from an Eastern Han tomb in Hanjiang County, Jiangsu. After restoration, they formed a flat-bottomed bowl with ridged decorations. Its composition, shape, and marvering technique are typical of Roman glassware, providing physical evidence of Western glass entering China. Additionally, blue flat glass plaque ornaments, unseen elsewhere in China, were unearthed from the tomb of the Nanyue King in Guangzhou. During the Wei, Jin, and Northern and Southern Dynasties, Western glassware was imported into China in large quantities, also introducing glassblowing technology. Due to innovations in composition and technology, glass containers from this period were larger, with thinner walls, and were transparent and smooth. A glass convex lens was unearthed from the tomb of Cao Cao’s clan in Bo County, Anhui; a glass bottle was unearthed from the pagoda foundation of a Northern Wei pagoda in Dingxian, Hebei; and many ground glass cups were unearthed from an Eastern Jin tomb at Xiangshan in Nanjing, Jiangsu. The most exquisite examples are arguably the eight glass vessels unearthed from the Sui Dynasty tomb of Li Jingxun in Xi’an, Shaanxi. They included flat bottles, round bottles, boxes, egg-shaped objects, tubular objects, and cups, all completely intact.

During the Eastern Zhou period, the shapes of glass objects increased. Besides ornaments like tubes and beads, bi-disc objects and sword fittings like guards, pommel ends, and scabbard slides were found. Glass seals have also been unearthed in Sichuan and Hunan. Glassware from this period was of purer quality, with colors including white, light green, cream yellow, and blue. Some glass beads featured layered “dragonfly eye” patterns. For instance, 73 dragonfly eye-style glass beads, each about 1 cm in diameter, were unearthed from the tomb of Marquis Yi of Zeng in Suixian County, Hubei, with white and brown glass patterns embedded on the blue glass sphere. Academic analysis of Warring States mid to late period glass beads and bi-discs found that most were composed of lead oxide and barium oxide, differing significantly from the composition of ancient European, West Asian, and North African glass. Therefore, academia believes they were likely produced locally in China.

V. Spraying Process

A glass bottle spraying production line generally consists of a spray booth, overhead conveyor, and oven. Pre-treatment water processing is also involved, with special attention needed for wastewater discharge. The quality of the spray coating depends on water treatment, workpiece surface cleaning, the conductivity of the hangers, air volume, the amount of powder sprayed, and the skill of the operator. The following methods are recommended:

Pre-treatment Stage: Includes pre-degreasing, main degreasing, and surface conditioning. In northern regions, the temperature of the main degreasing section must be maintained and not too low, otherwise the treatment effect is unsatisfactory.

Pre-heating Stage: After pre-treatment, bottles enter the pre-heating stage, usually for 8-10 minutes. It’s best for the workpiece to retain some residual heat upon reaching the spray booth to increase powder adhesion.

Blow-off and Purification Stage: Essential for high-precision工艺要求 (process requirements – implies high-quality finishes). Otherwise, dust吸附 (adsorbed) on the workpiece will result in a grainy surface after processing, reducing quality.

Drying Stage: Key factors are temperature and baking time. Powder typically cures best at 180–200°C, depending on the workpiece material. The drying oven should not be too far from the spray booth, ideally about 6 meters.

Spraying Stage: The most critical aspect is the technician’s skill. Investing in a skilled technician is worthwhile for achieving superior quality.

VI. Packaging Industry

The main characteristics of glass packaging containers are: non-toxic, odorless; transparent, aesthetically pleasing, good barrier properties, impermeable, abundant and common raw materials, low price, and reusable multiple times. They also possess advantages like heat resistance, pressure resistance, and cleanability, allowing for both high-temperature sterilization and low-temperature storage. Due to these many advantages, glass is the preferred packaging material for many beverages like beer, fruit tea, and wild jujube juice. Globally, 71% of beer is filled into glass beer bottles. China has the world’s highest usage rate of glass beer bottles, accounting for 55% of the global total, exceeding 50 billion bottles annually. As the mainstream packaging for beer, glass bottles have endured a century of changes in beer packaging. They remain favored by the beer industry for their stable material structure, lack of pollution, and low cost. “When companies want packaging with a beautiful appearance and a cool feel, glass bottles are the preferred packaging.” Overall, glass bottles remain the conventional packaging for beer companies and have made significant contributions to beer packaging, being loved by most people.

VII. Museum

The Glass Bottle Museum is located on the north side of the Sukhumvit Road bypass, on the eastern side of Pattaya City, Thailand. This museum was founded by the Dutch Mr. Bijl De Leij. It is an inconspicuous museum of glass bottle art. The museum houses over 300 exquisitely beautiful creations. Many famous large buildings, such as Bangkok’s Wat Phra Kaew (Temple of the Emerald Buddha), Wat Arun (Temple of Dawn), Wat Benchamabophit (Marble Temple), the Victory Monument, the Democracy Monument, as well as Thai-style temples, are all built inside glass bottles. These miniature buildings are constructed with such precise scale, fine detail, and perfect beauty within the confines of a small bottle mouth. One can imagine the painstaking effort and time required to condense such artistically beautiful structures into individual glass bottles, a difficulty arguably comparable to building the actual monuments.

Glass Products are made from more than ten kinds of raw materials including cullet (crushed glass), soda ash, sodium nitrate, barium carbonate, and quartz sand. They are formed through processes involving melting at 1600°C high temperatures. Different molds can produce various shapes of glass bottles, including various wine bottles, beverage bottles, pickled vegetable jars, honey jars, cans, soda bottles, carbonated drink bottles, coffee bottles, tea cups, and various irregularly shaped glass bottles like 0.5kg/2.5kg/4kg wine jugs. Glass bottles are sealed, transparent, and can long-term preserve products highly sensitive to humidity.

VIII. Manufacturing Process

The glass bottle production process mainly includes:

① Raw material pre-processing: Crushing bulk raw materials (quartz sand, soda ash, limestone, feldspar, etc.), drying damp raw materials, and removing iron from iron-containing raw materials to ensure glass quality.

② Batch preparation: Mixing the raw materials in precise proportions.

③ Melting: The glass batch is heated at high temperature (1550~1600°C) in a tank furnace or crucible furnace to form a uniform, bubble-free liquid glass suitable for forming.

④ Forming: The liquid glass is placed into molds to create glass products of the required shape, such as flat glass or various vessels.

⑤ Heat treatment: Processes like annealing or tempering are used to eliminate or create internal stress, induce phase separation or crystallization, and change the structural state of the glass.

IX. Advantages in the Field (Beverage Packaging)

Glass packaging materials and containers offer multiple advantages:

Excellent barrier properties, effectively preventing the invasion of oxygen and other gases, and preventing the volatilization of the contents’ components into the atmosphere.

Reusable multiple times, reducing packaging costs.

Color and transparency can be easily altered.

Safe, sanitary, with good corrosion and acid resistance, suitable for packaging acidic substances (e.g., fruit and vegetable juice drinks).

Suitable for automatic filling production lines. Domestic automatic glass bottle filling technology and equipment are relatively mature, giving glass bottle packaging for fruit and vegetable juice drinks certain production advantages in China.

X. Production Flow (Detailed)

First, the mold must be designed, confirmed, and manufactured. Glass raw materials, primarily quartz sand, along with other auxiliary materials, are melted into a liquid state at high temperatures. This liquid is then injected into the mold, followed by cooling, finishing the neck (e.g., “cracking off” the excess), and annealing (heat treatment to relieve stress) to form the glass bottle. Glass bottles usually have permanent markings (mold seams, logos) also formed by the mold shape.

Glass bottle forming can be divided into three methods according to the manufacturing technique: manual blowing, machine blowing, and pressing.

Glass bottles can be categorized by composition as follows:

Soda-lime glass

Lead glass

Borosilicate glass

The main raw materials for glass bottles are natural minerals, quartz rock, caustic soda, limestone, etc. Glass bottles are highly transparent and corrosion-resistant; contact with most chemicals does not alter their material properties. The manufacturing process is relatively simple, allowing for free and varied shapes. They are hard, heat-resistant, clean, easy to clean, and reusable. As a packaging material, glass bottles are widely used for food, oil, alcoholic beverages, drinks, condiments, cosmetics, and liquid chemical products. However, glass bottles also have disadvantages, such as high weight, high transportation and storage costs, and low impact resistance.

Usage Characteristics and Types: Glass bottles are primary packaging containers for the food, pharmaceutical, and chemical industries. They offer advantages like good chemical stability; easy sealing and good airtightness; transparency allowing visual inspection of contents; good storage performance; smooth surface facilitating disinfection and sterilization; aesthetically pleasing shapes with rich decorations; and certain mechanical strength to withstand internal pressure and external forces during transportation. Raw materials are widely distributed and low-cost. Their disadvantages are high weight (high mass-to-capacity ratio) and brittleness, making them prone to breakage. However, new technologies like lightweighting (thin-walling) and physical/chemical toughening have significantly improved these drawbacks. Consequently, glass bottle production has increased yearly despite fierce competition from plastics, tinplate cans, and aluminum cans.

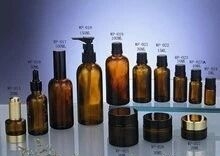

Glass bottles come in a vast variety, from 1mL small vials to large jars of several liters, from round and square to irregular shapes and handled bottles, from colorless transparent to amber, green, blue, black (light-blocking), and opaque opal glass bottles—the list is endless.

In terms of manufacturing technology, glass bottles are generally divided into two categories: molded bottles (made using molds) and tubular bottles (made from glass tubing). Molded bottles are further divided into wide-mouth bottles (mouth diameter >30mm) and narrow-mouth bottles. The former are used for powders, solids, and pastes, the latter for liquids. Based on mouth finish, they include cork-stoppered mouths, threaded mouths, crown cap mouths, roll-on mouths, and ground glass mouths. Based on usage, they are divided into “one-way bottles” (used once and discarded) and “returnable bottles” (multiple reuse). Classified by content, they include wine bottles, beverage bottles, oil bottles, canning jars, acid bottles, medicine bottles, reagent bottles, infusion bottles, cosmetic bottles, etc.

XI. Quality Standards & Standardization System

Standards and Standardization System for Glass Bottles

Article 52 of the “People’s Republic of China Drug Administration Law” stipulates: “Packaging materials and containers that directly contact drugs must meet pharmaceutical requirements and safety standards.” Article 44 of the “Implementing Regulations of the People’s Republic of China Drug Administration Law” states: “The management measures, product catalog, pharmaceutical requirements, and standards for packaging materials and containers that directly contact drugs shall be formulated and published by the drug regulatory department under the State Council.”

According to these laws and regulations, the National Medical Products Administration (NMPA) has progressively organized the formulation and release of 113 drug packaging container (material) standards (including those planned for 2004) since 2002. Among these, 43 are standards for medicinal glass packaging containers (materials), accounting for 38% of the total drug packaging standards. The scope of these standards covers medicinal glass packaging containers for various dosage forms including injectable powders, injections, infusions, tablets, pills, oral liquids, freeze-dried products, vaccines, and blood products. A relatively complete and standardized medicinal glass standardization system has been initially formed. The formulation, release, and implementation of these standards are of pivotal significance and function in updating medicinal glass packaging containers, improving product quality, ensuring drug quality, accelerating alignment with international standards and the international market, and promoting the healthy, orderly, and rapid development of China’s pharmaceutical glass industry.

Medicinal glass bottles are packaging materials that directly contact drugs, hold a significant proportion in the drug packaging field, and possess irreplaceable性能和优势 (performance and advantages). Their standards crucially impact drug packaging quality and industry development.

Standardization System for Medicinal Glass:

Following the NMPA principle of establishing one standard per material (type), 43 standards for medicinal glass have been released or are pending release. They are divided into three types by standard category:

Type 1: Product Standards (23 items total): 18 released, 5 planned for 2004.

Type 2: Test Method Standards (17 items total): 10 released, 7 planned for 2004.

Type 3: Basic Standards (3 items total): 1 released, 2 pending release in 2004.

The 23 Product Standards are divided into 8 types by product: 3 standards each for Molded Injection Vials, Tubular Injection Vials, Glass Infusion Bottles, Molded Medicinal Bottles, Tubular Medicinal Bottles, Tubular Oral Liquid Bottles; 2 standards for Ampoules; and 3 standards for Glass Medicinal Tubing (a semi-product for processing various tubular bottles and ampoules).

By material, they are divided into three classes:

Borosilicate Glass (8 standards): Includes neutral glass with α = (4~5)×10⁻⁶ K⁻¹ (20~300°C) and 3.3 borosilicate glass with α = (3.2~3.4)×10⁻⁶ K⁻¹. This material is international neutral glass, often called Type I glass or Class A material.

Low Borosilicate Glass (8 standards): α = (6.2~7.5)×10⁻⁶ K⁻¹. This is a material unique to China, a quasi-neutral glass not fully aligned with international standards, often called Class B material.

Soda-Lime Glass (7 standards): α = (7.6~9.0)×10⁻⁶ K⁻¹. This material is generally sulfur-treated, achieving a Hydrolytic Resistance (surface) of Grade 2.

The 17 Test Method Standards largely cover the testing of various properties and indicators for all types of medicinal glass products. Notably, for assessing chemical performance, new tests for hydrolytic resistance, alkali resistance, and acid resistance have been added referencing ISO standards. This provides more comprehensive and scientific detection methods for evaluating chemical stability, ensuring medicinal glass bottles are suitable for different drug properties and dosage forms. Methods for testing the leaching of harmful elements have also been added to ensure drug safety. Further supplementation of test methods is needed, e.g., for ampoule alkali resistance (delamination), breaking force, and resistance to thermal shock from freezing, which significantly impact quality and application.

The 3 Basic Standards include “Classification and Test Methods for Composition of Medicinal Glass,” which references ISO 12775-1997. It provides a clear definition for classifying medicinal glass composition, distinguishing it from classifications in other industries. The other two basic standards set limits on harmful elements like lead, cadmium, arsenic, and antimony in the glass composition to ensure the safety and efficacy of the packaged drugs.

Characteristics of Medicinal Glass Standards:

Medicinal glass standards are a crucial branch of the drug packaging standard system. Because they directly contact drugs, sometimes for extended storage periods, their quality directly affects drug quality and human health and safety. Thus, these standards have special, strict requirements:

Systematic and Comprehensive: Enhances selectivity and overcomes obsolescence by categorizing standards by material for each product type.

Clarified Definitions: Clearly defines borosilicate glass (B₂O₃ >8% m/m) and low borosilicate glass (B₂O₃ 5-8% m/m), distinguishing Chinese-specific material.

Adoption of ISO Standards & International Alignment: Aligns glass types (3.3 Borosilicate, 5.0 Borosilicate, Low Borosilicate, Soda-Lime), material properties (thermal expansion coefficient α, chemical composition like B₂O₃%), and product performance (hydrolytic resistance, thermal shock, internal pressure) with international standards (ISO, USP, etc.), often with stricter requirements (e.g., internal stress for ampoules is 40 nm/mm vs. ISO’s 50 nm/mm). Notes specific Chinese contexts (e.g., low boron ampoules as transitional).

Shift Towards Trade-Oriented Standards: Standard format emphasizes identification (α, B₂O₃ content). Key performance and safety limits are mandatory in the main text. Appearance details and specific dimensional tolerances can be agreed upon between supplier and buyer, though dimensional tolerances in appendices should be mandatory.

Comprehensive Testing & Complete Supporting Standards: Testing is comprehensive, including added tests for α, B₂O₃%, and leaching of harmful elements (As, Sb) from澄清剂 (clarifying agents). Most test methods align with ISO. Notes need for further complementary test methods.

Complete Supporting Standards: Relatively complete set of supporting test standards exists.

Application of Medicinal Glass Standards:

The matrix of standards allows for scientific, rational selection based on:

Chemical Stability: Choose based on drug compatibility. High-end drugs (blood products, vaccines, strong alkaline injections) require borosilicate glass (Type I). General powders, orals, infusions may use low borosilicate or treated soda-lime glass. Low boron ampoules for injections are not ideal and should transition to 5.0 borosilicate. Alkaline liquids are more aggressive than acidic.

Thermal Shock Resistance: Depends on coefficient of thermal expansion (α). Lower α means better resistance. High-end products (vaccines, biologics, freeze-dried) should use 3.3 or 5.0 borosilicate glass. 3.3 Borosilicate is particularly good for freeze-drying. Low boron glass can crack under large thermal gradients.

Mechanical Strength: Borosilicate glass generally has better mechanical strength than soda-lime glass, relevant for handling and transport.

The new standards promote a scientific system, international alignment, improved quality, and industry development, though continuous improvement is needed.

Glass Container Testing Standard Example: Glass Container Stress Test Method: ASTM C 148-2000(2006)

XII. Energy Saving & Environmental Protection

Over the past decade, global practice in glass furnace technological transformation has shown that full oxy-fuel combustion technology offers significant advantages: low investment, low energy consumption, and low pollutant emissions. In the US and Europe, lightweight bottles dominate the glass container market. Advanced technologies like Narrow Neck Press and Blow (NNPB) and cold-end and hot-end coating are used for lightweight production. German companies can produce 1-liter浓缩果汁 (concentrated juice) bottles weighing only 295 grams, coated with organic resin to increase pressure strength by 20%.

In modern factories, producing glass bottles involves overcoming significant scientific challenges. Glass bottles are ubiquitous in daily life, used for beverages, medicine, cosmetics, etc. They are consistently regarded as premium packaging materials due to their transparent beauty, excellent chemical stability, non-contamination of contents, ability to withstand high temperatures, and the recyclability of used bottles.